We’re proud to work with innovative partners who share our commitment to excellence. Together, we create solutions that make an impact.

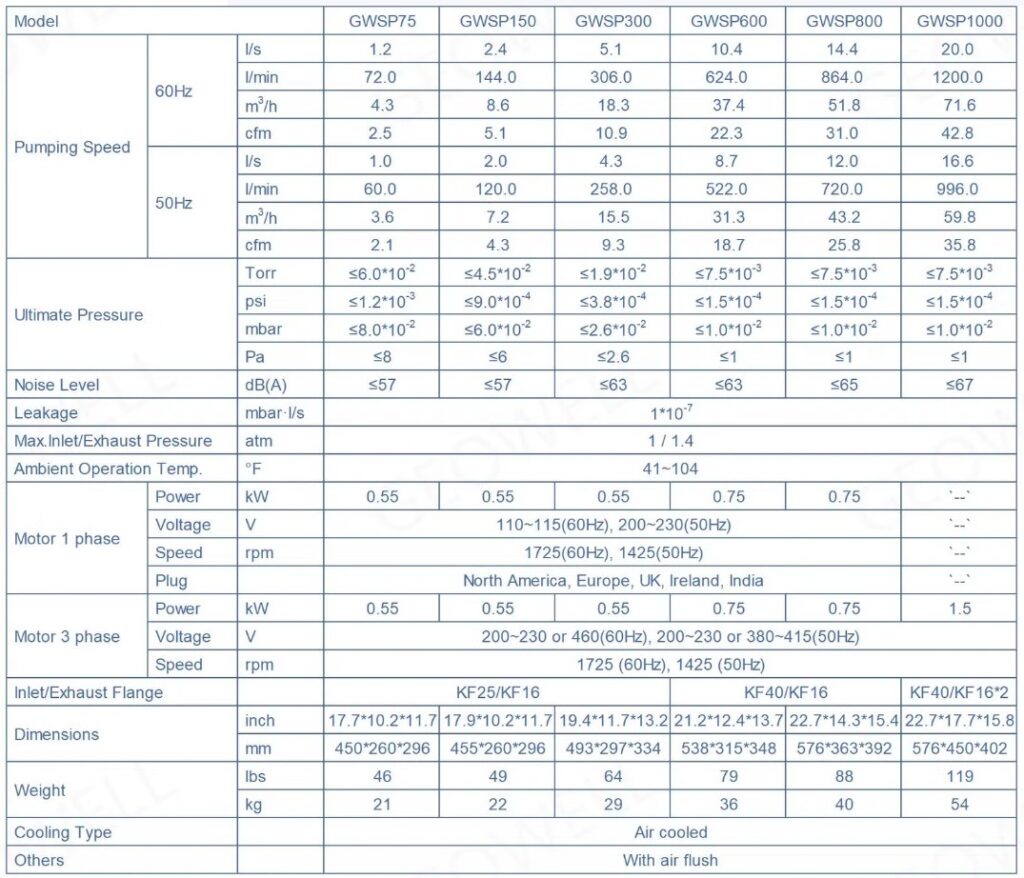

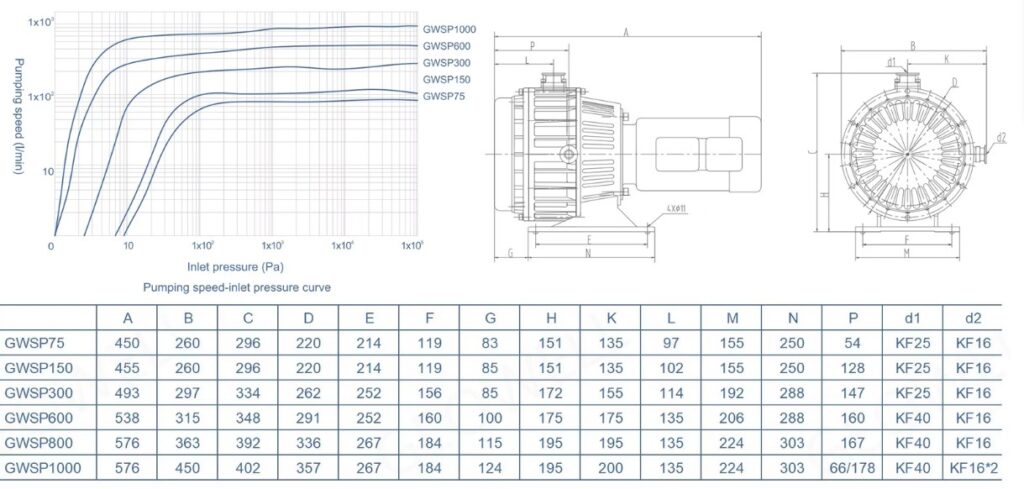

>>> No oil clean vacuum

No oil back-diffusion, no oil mist exhaust, provide a clean vacuum environment

>>> Wide product lineup

Pumping speed covers 3~60 m3/h, limited vacuum level 1~8 Pa

>>> Low vibration, low noise

54~63 dB(A), smooth operation

>>> High efficiency, ease of maintenance

No water cooled, no oil lubricated, no daily maintenance

>>> Suitable for all types of power supplies around the world

110/220/380/460V, 50/60Hz for choose

GWSP oil free scroll vacuum pump is constructed with pump head assembly, crank pin assembly, bracket assembly, air flush assembly, and exhaust valve assembly. Two spiral cylinders, one offset and orbiting against the other fixed with an offset of 180° to form several crescent-shaped pockets of different sizes. By means of an eccentric drive, the orbiting scroll is made to orbit about the fixed scroll, reducing the volume of the pockets and compressing gas from outside towards the inside thereby pumping the gas from vacuum chamber.

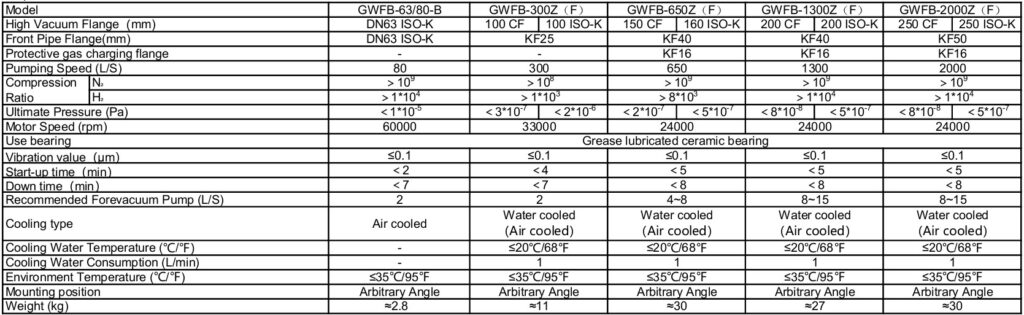

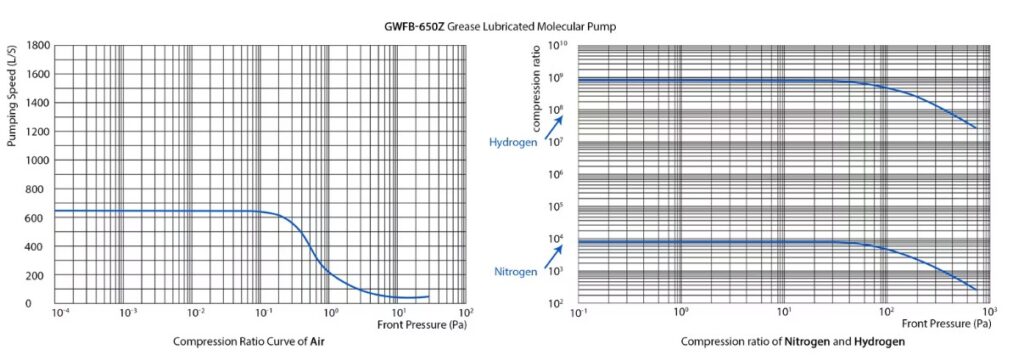

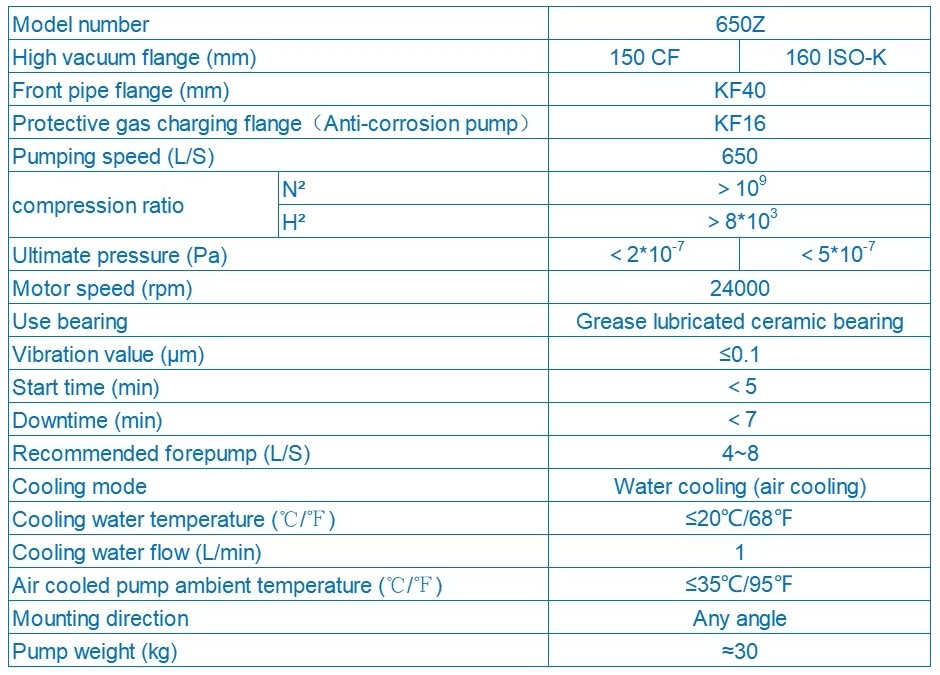

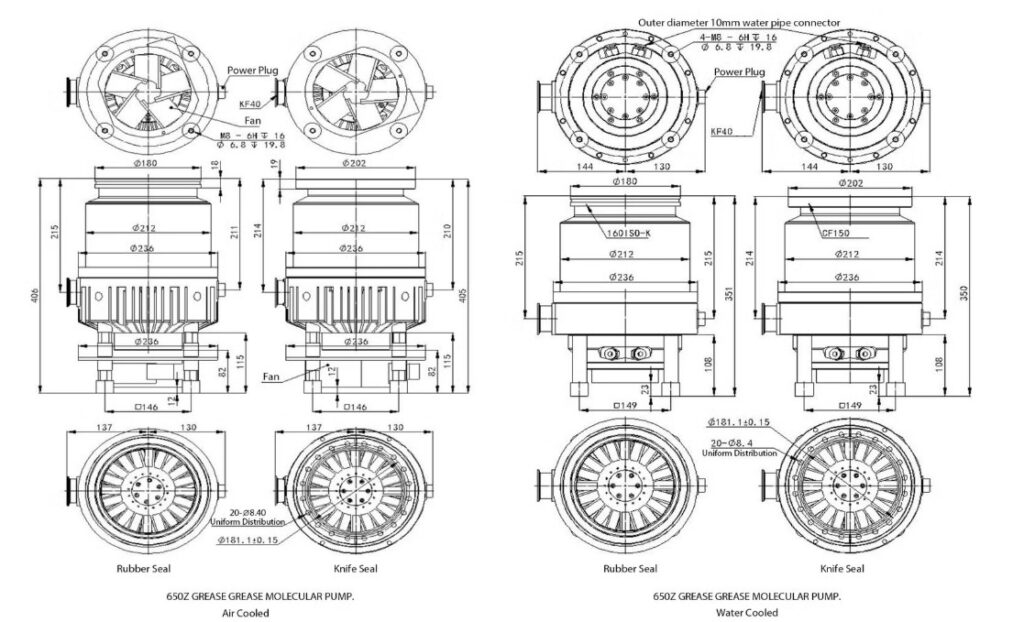

>>> Model Number GWFB-650Z-QVT

>>> Pumping Speed 650 L/s (for Nitrogen)

>>> Oil Status Oil-free (can also be grease-lubricated depending on specific variant)

>>> Cooling Air or water-cooled

>>> Ultimate Pressure Capable of achieving ultra-high vacuum levels

>>> Rotation Speed Typical operating speeds for similar pumps are high, often in the range of 60,000 rpm or higher

>>> Applications Mass spectrometry, environmental simulation, vacuum coating, semiconductor manufacturing, laser/LED applications

GWFB-650-QVT is an oil-free turbo molecular vacuum pump delivering approximately 650 L/s pumping speed with ultimate pressure down to the 10⁻⁷ Pa range, designed with grease-lubricated ceramic bearings for high reliability, CF or ISO-K inlet flange options with KF40 foreline connection, water- or air-cooling capability, fast start-up and stable operation in any mounting orientation, making it suitable for semiconductor processing, vacuum coating, analytical instruments, and research systems requiring clean, high-vacuum performance.

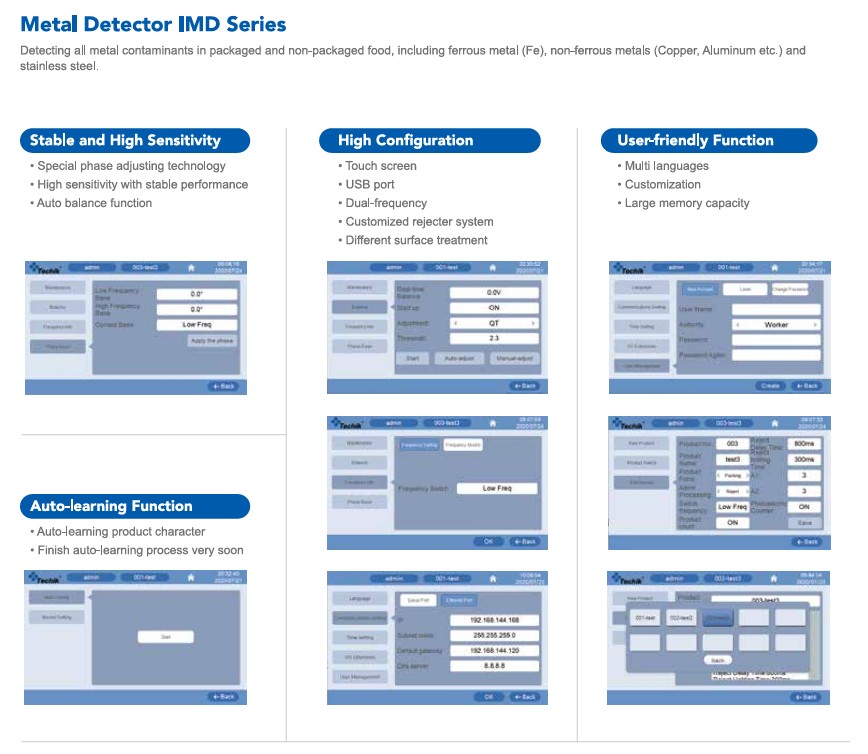

The first DSP metal detector suitable for metal contaminants detector in various industries like aquatic products, meat & poultry, salted products, pastry, nuts, vegetables, chemical raw materials, pharmacy, cosmetics, toys , etc.

Metal Detection System – Advanced industrial metal inspection solution using high-sensitivity detection technology to identify and reject ferrous, non-ferrous, and stainless-steel contaminants, ensuring product safety, process reliability, and compliance across food, pharmaceutical, and manufacturing applications.

Walk-Through & Security Metal Detectors

• TE-SD2 Thermo Walk-Through Metal Detector – Full digital walkthrough detector with adjustable zones (1/8/16/24), infrared temperature measurement, high sensitivity, and visual/audible alarms for security screening environments.

• TE-SD2 Walk-Through Metal Detector – Standard security walkthrough detector using DSP tech with up to 300 sensitivity levels and multiple detecting zones for person screening.

• TE-SC2 Handheld Metal Detector – Portable handheld detector with buzzer/vibration alerts and adjustable sensitivity for quick spot scanning.

Conveyor & Industrial Metal Detectors

• Conveyor Belt Metal Detector (IMD Series) – DSP conveyor type system for detecting ferrous/non-ferrous/stainless contaminants in food & manufacturing lines, with models like IMD-4008/4012, 5020/5025, 6025/6030 offering different belt widths and detection heights.

• High Configuration Conveyor Belt Metal Detector (IMD-H Series) – Enhanced conveyor detectors with dual-frequency, touch screen, auto balance, and variable speed options for higher stability and sensitivity.

• Gravity Fall Metal Detector (IMD-P) – Compact gravity-feed metal detector for bulk powders or granular products with automatic reject mechanisms.

Specialized / Variant Models

• Metal Detector for Biscuits (IMD-B) – Belt metal detector designed for confectionery, with pneumatic retracting band rejecter to maintain product order.

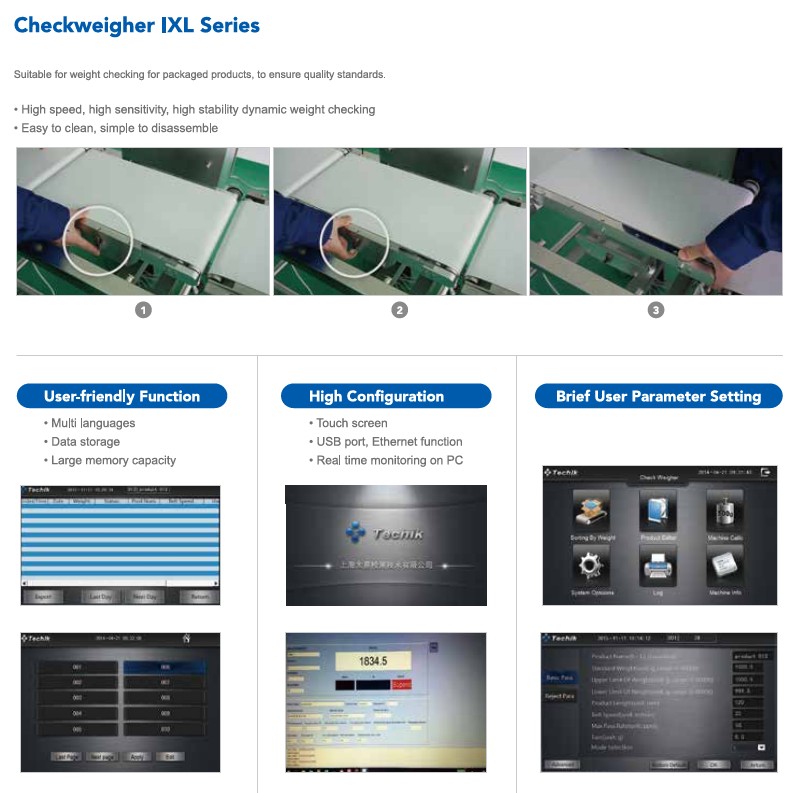

High-Speed Dynamic Checkweigher (IXL-Series) – Online high-speed, high-sensitivity dynamic weigh check system with 7″ touch screen, multi-language UI, large memory, and automatic reject for under/over-weight packaged products in food, pharma & consumables, with models covering various weight ranges and speeds (e.g., 10–600 g to 0.2–10 kg; up to ~250 pcs/min) for precise inline weight inspection and sorting.

Checkweigher for Small Packages – Compact dynamic checkweigher with stainless steel frame, food-grade belt, high speed and stability, plus customizable rejectors (air jet/pusher/flipper) for weight checking and rejection of small packaged goods.

General Checkweigher Features (applicable across models) – High speed and sensitivity, easy-clean hygienic design, multi-language touch panel, large data storage, various rejectors, and weight data recording for compliance, quality control, and feedback-loop optimization.

These systems collectively detect a wide range of contaminants (metallic & non-metallic) across various production needs, operate with hygienic stainless-steel design and safety standards (<1 μSv/h leakage), and integrate automatic reject mechanisms for quality control in food, beverage, pharmaceutical, and packaging lines.

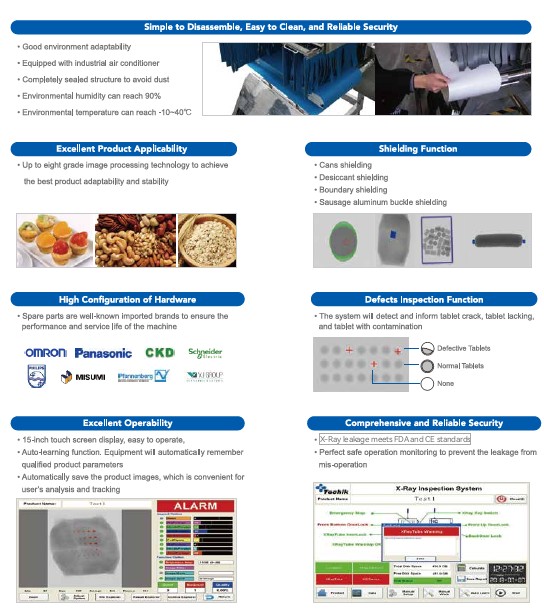

Standard X-ray Inspection System (TXR Series) – Inline X-ray inspection with penetrating detection of metal & non-metal contaminants (glass, ceramic, stone, bone, plastic) across multiple model widths/heights (e.g., 2480/4080/5080/6080), Windows-based operation, 15″ touch control, auto-learning, and optional rejecters for secure, hygienic food/package quality inspection.

Quantum Vacuum Technologies

Lawrence Ng

Hey, how can I help you today?

Powered by Elementor